Dynamic Weighing for accurate Fertilizer Application

The mass flow of fertilizer spreaders must be calibrated for different

types of fertilizer. To obtain an accurate fertilizer application a manual

calibration procedure has to be repeated frequently.

An automatic calibration is possible when actual fertilizer mass flow is

known. One method to determine mass flow is to monitor the weight decrease

of the spreader during fertilizer application. When spreader weight differs

significantly from the applied amount of fertilizer according to the current

calibration, the dose controller calibration is adjusted.

In this research a dynamic weighing system for automatic flow controller

calibration is presented (figure 1). Monitoring of spreader weight also

offers the opportunity to log spreader performance, which is important for

on farm evaluation of crop yield to the applied fertilizer strategy.

Materials and Method

Two strain gauge load cells are mounted on a frame between tractor

hitch and spreader as sketched in the figure below. The entire spreader

rests vertically on load cell A, suspended by a reversed parallellogram.

Load cell B measures a known load which gives information on vertical

acceleration and on inclination of the spreader.

Results

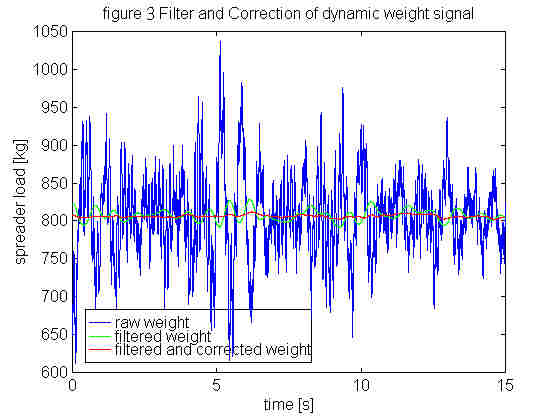

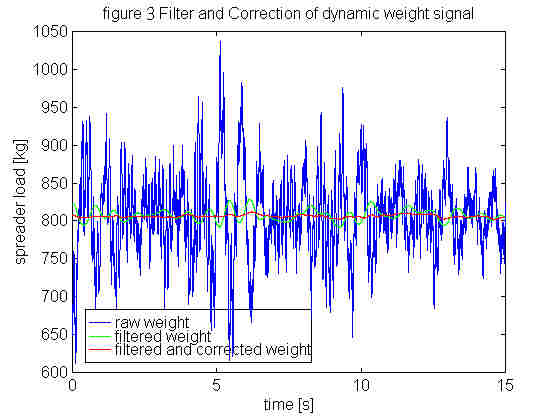

The dynamic weighing filter algorithm consists of a low pass filter for

the load cell signals and a proportional correction from load cell B on

load cell A. Figure 3 shows the results of filtering and correction of a

dynamic signal acquired at 2 m/s driving velocity on rough surface.

The filter and correction procedure delay is 1 second and the standard

deviation of the determined mass is 1.8 kg for this experiment.

The algorithm to adjust the calibration of the flow controller is based

on a linear regression between predicted weight decrease at current calibration

and weight decrease measured by dynamic weighing.

A calibration adjustment is permitted when the level of the 99% confidence

interval of this linear regression coefficient is equal to or below the

accuracy of the current calibration.

With an initial calibration accuracy preset at 10%, a simulation shows how

the algorithm starts to adjust calibration after a mass decrease of 35 kg.

A calibration accuracy of 1% is reached after spreading approximately 150 kg.

of fertilizer.

From research environment to farm practice

For the 1997 season the above described dynamic weighing system

has been implemented on a farmer's equipment. The objectives where

to record actual applied amount of fertilizer to be able to relate

yield maps to fertilizer strategy in an on farm evaluation of

precision farming.

A dual spinning disc type fertilizer spreader

for mineral fertilizers is weighed continuously. Fertilizer rate

settings and applied amount are recorded by equipment

mounted in the tractor. Tractor operating conditions like

motor RPM, radar and wheel velocities and position (DGPS) complete

the dataset. See tractor and spreader while loading fertilizer:

A detailed view on the weight measuring implementation; the

orange painted weighing derrick equipped with load cells between the

spreader and tractor.

A view inside the tractor cabine. Two computers reside on board; leftside

the

Mueller Elektronik equipment to control the fertilizer rate dependent of

driving speed and to record task data. On the righthand the touchscreen of the

datalogging equipment.

The datalogging computer is mounted beside the chair; yes, it 's becoming

busy in the cab, but luckily a place was found for the strain gauge

amplifier on top of the former passenger seat. Finally, the DGPS system

was small enough to reside near the computer.

Post processing of the obtained data yielded maps of applied fertilizer.

The detailed measurements indicated fertilizer flow actuator malfunctioning

which the farmer previously had noticed too. Additional EMC suppression was

needed to increase accuracy of the fertilizer rate control.

For the 1998 growing season the strain gauge amplifier is going to be

replaced by an integrated sigma delta converter. The system will be

modified to be able to connect an Agricultural BUS for electronic

data transfer. A Controller Area Network (CAN) node on the spreader

performs dynamic weighing and control of the spreader and is connected

through CAN to the boardcomputer running a virtual terminal and taskcontroller.

The picture below shows the single board computer to be used as electronic

heart of the fertilizer spreader. It features a Siemens SAB167 16-bit

microcontroller with integrated CAN bus controller.

Back to Index

Back to Index